Looking ahead to 2015, we will certainly take a deep dive into gear and disc couplings, as well as into any particular questions or topics that website visitors request. This blog has been designed expressly to be a tool for the general flexible coupling user. If you have questions that we haven't answered, or haven't answered to your liking, please let us know. Not only do we want to help you, but we also want to help others who likely have questions similar to you. (Chances are very good that if you've got a question, several hundred others will have a very similar question and will be seeking it out online.)

While blog posts that were posted earlier in the year tend to have more views, and we expect some of our most recent posts to pop over time... for the sake of posterity, we wanted to record what were the Top 10 most viewed blog posts for this site's first year.

Without further ado... here they are (with #1 being the most viewed/most popular):

#10. Jaw In-Shear Couplings - A Straight Forward Value Add

#10. Jaw In-Shear Couplings - A Straight Forward Value AddThis article takes a deep dive into the jaw in-shear coupling, which, leveraging two standard Lovejoy jaw coupling hubs and a radially removable elastomeric spider and retaining ring, turns a traditionally fail-safe design into a non-fail safe design. The design provides for rapid elastomeric spider inspection and replacement without moving the hubs or use of any external tools (only your hands).

#9. Coupling Spacers - How Long Can or Should They Get?

The purpose of a coupling spacer is not always well understood, nor are the trade-offs and drawbacks of having longer ones. This article dives into the pros (allowing equipment to be spaced far apart if required, greater misalignment handling...) and cons (cost, overhung load, weight....) of coupling spacers, and also talks about several technologies (inclusive of composite materials). This article is an ideal starting point for anyone considering the trade-offs of a spacer couplings.

#8. Flexible Coupling Basics - A Quick Primer

This article provides a broad overview of many different flexible coupling types, inclusive of elastomeric (with flexing rubber elements) and metallic (gear, grid, disc) types is an excellent starting point for someone new to the power transmission industry. The article is also ideal for those looking to better understand the flexible coupling market space from a high 30,000 foot level.

#7. Coupling Sizing Torque - How to Quickly Calculate (inclusive of Service Factor)

#7. Coupling Sizing Torque - How to Quickly Calculate (inclusive of Service Factor)

This post provides tools (both online and for smart phones) that allow a user to quickly calculate the required torque of a coupling, and to then be able to quickly select a coupling based on that calculation.

This post is an ideal read for anyone who needs to make coupling selections on a regular basis, and or anyone who needs to calculate required torque (based on horsepower, rpm, and service factor) regularly.

#6. Jaw Coupling Overview - Features & Benefits, Design Basics, and Element Options

#6. Jaw Coupling Overview - Features & Benefits, Design Basics, and Element Options This article was written to provide an excellent overview on the industry leading multi-purpose flexible jaw coupling. Lovejoy first launched the jaw coupling in 1927, drove it to be a widely accepted industry standard based on its technical merits (robust, affordable, low maintenance, etc.), and continues to hold a market leading position in the product line. Given Lovejoy's authority position on the jaw coupling, this article is an excellent starting point for anyone interested in learning more about jaw couplings.

#5. Coupler or coupling? Which one is correct?

#5. Coupler or coupling? Which one is correct? This article was driven by repeated conversations that are constantly occurring within the walls of Lovejoy. Some customers call our product "couplers" while the vast majority (inclusive of ourselves) call them "couplings". We wanted to dive into this issue a bit deeper, and provide our findings for all to enjoy.

#4. Clearance vs Interference Fit Couplings - Which Hub Fit is Better?

#4. Clearance vs Interference Fit Couplings - Which Hub Fit is Better? This is a common question we get, and one we felt was ideally suited to be answered on the blog.

There are benefits and drawbacks to each fit, and the better fit is certainly application specific. For further information on the trade-offs, please read the article!

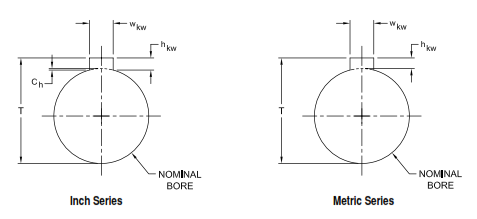

#3. Active Coupling Bore and Keyway Standards - What Are They & Where Can I Find Them?

#3. Active Coupling Bore and Keyway Standards - What Are They & Where Can I Find Them?Now we are getting into the blockbuster articles of 2014... the top 3. Earning the year's bronze metal is a posting that cleanly lays out the most common coupling bore and keyway standards, as well as direct links to where those standards can be downloaded. (Sorry, we don't have the authority or authorization to provide those standards without cost ourselves.)

If you are looking to better understand what the standards are, and where you can find them... this is a post for you!

#2. Cutting Keyways - Broaching, Keyseating, Wire-Cut EDM, Shaping, & Milling

This post was commissioned after the Lovejoy team realized that they could not find a solid comprehensive resource that covered this topic very well online. While many Lovejoy customers trust and rely on Lovejoy to provide final bore and keyways, there are also a substantial subset that like to have unfinished (rough stock) bores available on their shelves locally to address emergency breakdown situations.

This article was written to provide an overview of how any why keyways are cut to both to the end user who may require a keyway to be cut in the field, as well as to Lovejoy's many end users who may just want to better understand the technology Lovejoy is using to make their requested product.

#1. Coupling Failure Analysis - Jaw Couplings (includes hub & spider photos)

#1. Coupling Failure Analysis - Jaw Couplings (includes hub & spider photos) As discussed in a recap of #6 above, Lovejoy is the authority on jaw couplings. Given the sheer volume of the installed base, and the fact that manufacturers generally do not like to failures (even though most couplings have wearing components that are designed to be replaced over time), it's not surprising that the posting on jaw coupling failures was our number #1 most popular post for 2014.

We have since rolled out a similar article for grid couplings (see Grid Coupling Failure Analysis), and have several others planned an in the pipeline.

Thank you to all who have contributed to the success of both Lovejoy and the CouplingAnswers.com blog this year. We wish you a very happy and safe New Years, and a terrific 2015!

No comments:

Post a Comment